What are Backorders?

Backorders are orders accepted by a business for products that are currently out of stock but will be fulfilled once the inventory is replenished. Here’s how it works: when a customer places an order for an item that is not in stock, the business converts this order into a backorder. The customer is then notified about the delay in delivery and provided with an estimated time of arrival (ETA) for their order.

- Unlocking Arbitration in Finance: A Comprehensive Guide to Dispute Resolution in International Business

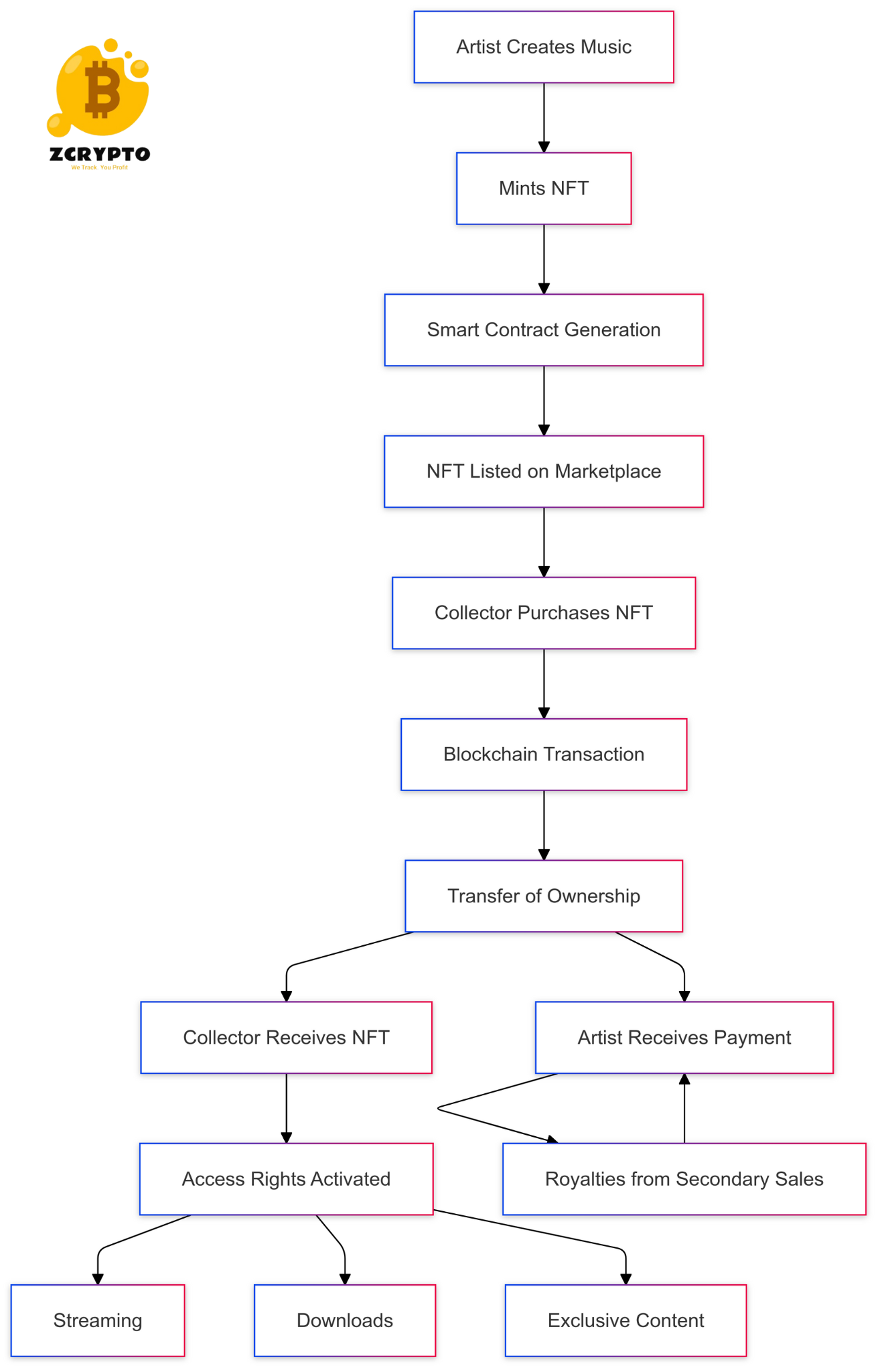

- What is NFT Marketplace? – ZCrypto

- Unmasking Boiler Room Scams: How to Protect Your Investments from High-Pressure Fraud

- Unlocking Your Account: A Comprehensive Guide to Understanding Your Account Number

- What is Metaverse? Current State and Technical Infrastructure

Once the product is restocked, the backorder is converted into a purchase order and shipped to the customer. Effective communication with customers during this process is crucial to manage expectations and maintain trust.

You are viewing: Mastering Backorders: How to Manage, Benefit, and Minimize Costs in Your Business

Causes of Backorders

Backorders can stem from several common issues within your inventory management system.

Low Safety Stock Levels

One of the primary causes of backorders is maintaining low safety stock levels. Safety stock acts as a buffer against unexpected increases in demand or delays in restocking. If your safety stock levels are too low, you may find yourself frequently facing stockouts.

Manufacturer or Supplier Problems

Supplier reliability is another critical factor. Issues such as late shipments or quality control problems with your suppliers can lead to stockouts and subsequent backorders. Relying on a single supplier increases this risk; diversifying your suppliers can mitigate it.

Inaccurate Demand Forecasting

Demand forecasting errors can also lead to backorders. If your forecasts underestimate demand, you may not have enough stock on hand to meet customer orders. Conversely, overestimating demand can result in overstocking but does not directly cause backorders.

Managing Backorders Effectively

Strategies for Minimizing Backorders

Setting Safety Stock Levels

Setting appropriate safety stock levels is essential in preventing backorders. This involves calculating the optimal amount of inventory to hold based on historical sales data, lead times, and service levels. Higher safety stocks reduce the risk of stockouts but increase holding costs.

Calculating and Setting Reorder Points

Accurate reorder points are crucial for maintaining inventory levels. These points should be based on sales cycles, lead times, and demand patterns. Automated systems can help in setting these points accurately.

Regularly Monitoring Inventory Levels

See more : Understanding the 25x Rule: How it Works and Key Considerations for Retirement Savings

Regular inventory checks and using inventory management software provide real-time data on stock levels. This helps in identifying potential stockouts early and taking preventive measures.

Best Practices for Handling Backorders

Communicating with Customers

Transparency is key when dealing with backorders. Communicating accurately with customers about delivery delays and providing ETAs helps manage their expectations and builds trust.

Using Automated Systems

Automated systems can significantly streamline the process of tracking stock levels in real-time, preventing backorders by alerting you when stocks are running low.

Managing Cash Flow

Backorders can impact your cash flow since you may receive payments before delivering the products. Strategies like pre-orders with partial payments can help manage operational costs during this period.

Financial Considerations and Costs

Backorder Costs

Backorder costs include direct costs such as expedited shipping fees, indirect costs like lost sales due to stockouts, and ambiguously estimated costs such as the opportunity cost of lost customer goodwill.

The friction cost analysis is a method used to calculate these costs by considering all aspects of the backorder process.

Accounting for Backorders

Special accounting processes are required for backorders. These include recording backorders as a subcategory of sales and handling potential cancellations or returns.

Pricing Strategies

Pricing strategies for backordered items can vary. You might consider slightly higher prices due to the inconvenience or offer discounts on future purchases to compensate for the delay.

Benefits of Backorders

See more : Understanding Banker’s Acceptance: A Safe and Liquid Investment for International Trade

Despite the challenges they present, backorders also offer several benefits.

Improved Customer Satisfaction

Allowing customers to pre-purchase items that are currently out of stock can improve customer satisfaction by securing advantageous sale prices or ensuring availability of popular items.

Streamlined Inventory Management

Backorders help in maintaining optimized inventory management systems by providing insights into which items are in high demand but currently out of stock.

Fine-tuned Inventory Predictions

Analyzing backorder data can provide valuable insights into customer demand patterns, helping you adjust your inventory levels accordingly.

Additional Resources or Further Reading

For further learning on backorder management and inventory optimization:

These resources will provide you with more detailed insights and tools to enhance your inventory management practices.

Source: https://summacumlaude.site

Category: Blog